Investor News

Hydrogen fuel scale challenge

It will be some time before hydrogen fuel cell vehicles (HFCV's) are widely available here in Australia and even longer before they make a dent in the market against electric (battery) vehicles, let alone the good old petrol and diesel vehicles that have been the backbone of transport since Benz patented his engine in 1879.

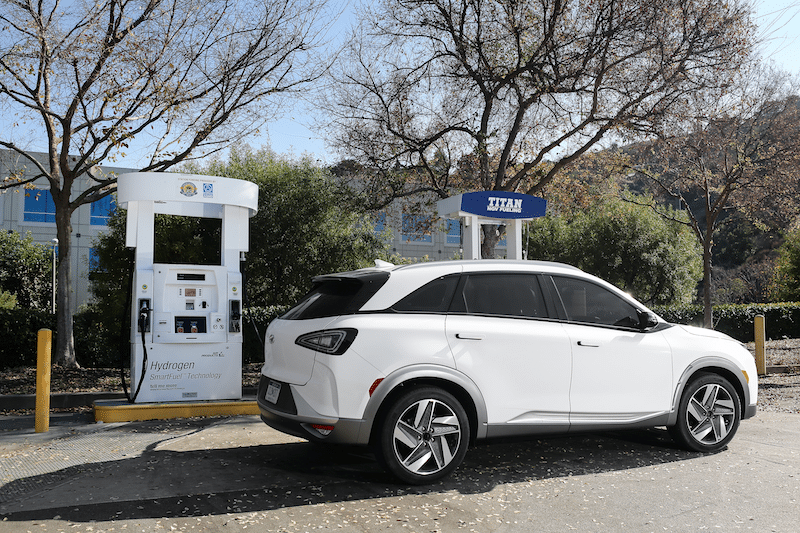

The below article from Drive.com.au highlights the latest from South Korea's Hyundai; the Nexo.

The vehicle is a welcome showcase of how the future of hydrogen could look and perform.

The Nexo is a 5-seat family SUV with a 600km range and a respectable 0-100kph in under 10 seconds. The interior takes its cues from Hyundai's luxury Genesis brand. It is due to hit Australian shores later this year as part of a sustainable energy project. Thereafter, Hyundai hopes to roll out HFCVs by 2025, complete with the latest autonomous driving features.

The cost?

Not yet disclosed. But Hyundai concedes it won't be cheap. No surprise there. Economy of scale is required before a new platform like this can compete on price. And then there's the hydrogen infrastructure challenge. Honda unveiled a home hydrogen fuelling station way back in 2007. A range of companies has worked on various home hydrogen units. Expect units to cost $5,000 plus and come in a number of 'flavours'; mains, wind or solar-powered, and in steam-gas reforming or electrolyser platforms.

There is a race for hydrogen.

We're part of that race.

Our COHgen process, which is still in early-stage fundamental R&D, aims to generate hydrogen from brown coal.

We look forward to discussing how the COHgen process works when we complete our fundamental research and file a patent, but until then, all we can say is that the objective is to deliver a low-emission hydrogen production process that is cheaper than incumbent methods: steam-natural gas reforming (gas 'cracking') and water electrolysis.

Most of the world's hydrogen currently comes from a gas 'cracking' process, which is expensive and CO2 intensive.

Alternatively, water hydrolysis can be used to generate hydrogen. However, this is energy-intensive and more expensive than cracking natural gas.

More info on traditional hydrogen production can be found here.

CSIRO is considering using excess wind generation to power hydrolysis, effectively storing the unused wind energy as hydrogen for vehicles. UK-based ITM Power already has modular hydrogen generation solutions (link).

The problem with that approach is scale.

The amount of 'spare' wind electricity in Australia is limited. As such, we couldn't produce much hydrogen, and what we could produce would suffer from a high rate of production variability as residential and business needs were prioritised against a backdrop of intermittent wind conditions.

And building wind farms for dedicated hydrogen production also suffers from scale issues.

How many 3MW wind turbines would we need to make enough hydrogen to power Australia's cars?

Let's do a quick back-of-the-envelope calculation:

Let's assume:

- We want all 13,712,810 passenger cars in Australia (ABS 2016) to run on hydrogen. At this point, we should forget heavy commercial vehicles like trucks and buses.

- Those cars travel 179,637,811,000 km (ABS 2016).

- Best practice electric vehicle efficiency of 6.25km per kWh is achieved across the fleet.

- Conversion of water to hydrogen via wind-based electrolysis is around 23% efficient at the fuel cell. That's 23kWh of hydrogen fuel cell output for the 100kWh of power it takes to make the hydrogen.

- Average wind capacity factor is 30%.

- Land required for wind turbines is 50 acres per megawatt (MW).

The outcome?

To split the water, we'd need ~15,851 3MW wind turbines covering ~9,622 square kilometres to produce the ~124.97TWh of electricity needed.

For context, Australia's total electricity production in 2016 was ~258TWh, and the total installed wind capacity at the end of 2017 was around ~4,500MW.

To make the switch to HFCVs, we would need to add ten times more wind capacity, none of which would power our homes.

Now, this clearly isn't a detailed assessment, just a quick calculation based on simple assumptions, but it shows the 'scale' challenge we need to overcome to produce economy-wide volumes of hydrogen using wind power. And so you know, I crunched the numbers on solar PV. It's a non-starter. We'd need 79,252MW of solar PV capacity, which is 13 times our current 6,000MW of installed capacity.

Alternatively, we think there may be a market for affordable, reliable hydrogen from Victorian brown coal using a relatively compact COHgen facility.

Our Coldry and Matmor technologies are just the beginning.

Read more below...

Hyundai: Hydrogen is the "ultimate solution"

Andrew Maclean | Drive.com.au | 9 Jan 2017

Hydrogen will become the fuel of the future, according to Hyundai.

The South Korean brand has been at the forefront of the development of fuel cell vehicles and was the first car maker to offer a hydrogen-powered vehicle for public sale, with the previous-generation ix35 FCV offered in South Korea and Europe.