Investor News

Shareholder Update - India Project

Environmental Clean Technologies Limited (ASX: ECT) (ECT or Company) is pleased to provide the following update on the progress of its India project with partners NLC India Limited (NLCIL) and NMDC Limited (NMDC).

Key points:

- Project financial close timeline guidance updated

- Agreement structure and naming refined

- Project funding ratified, disbursement approved following financial close

- NLCIL continue preparations for project site clearance and geotechnical survey activities

- Completion of the integrated basic design package and preliminary budget

- Indian engineering firm appointed to prepare tender packages

- ECT project management recruitment program nears completion

On 30 May 2018, the project partners signed a project agreement with NLCIL and NMDC for the largest-ever joint R&D collaboration between Australia and India.

The project agreement set the framework for the preparation and execution of detailed sub-agreements which will govern the implementation of the R&D phase and set the basis for articulation to the commercial phase following successful R&D outcomes.

Given the first-of-a-kind nature of the technologies and the project, the Company manages the uncertainties around changes in timeframes by providing ongoing guidance based on information at hand, with subsequent updates if there is a material change.

Revised Guidance for Financial Close

As stakeholders will be aware, the project partners have been closely monitoring progress against their target to conclude the drafting, review and approval of the Research Collaboration Agreement (formerly referred to as detailed sub-agreements) by 31 July 2018.

Recent guidance received from NLCIL and NMDC has revised the outlook, with estimates indicating financial close is likely to conclude around 21 - 25 August.

This revised guidance is a result of specific changes to the timing of the respective monthly board meetings for NLCIL and NMDC, which have been driven by statutory and annual reporting processes and director transitions (retirements). These factors have taken precedence over operational programs and required changes to the regular scheduling on which the project target date had been established.

In recent meetings with both NLCIL and NMDC director representatives, ECT has been provided with every assurance that its partners remain committed to achieving Financial Close as soon as possible and, notwithstanding their recently requested changes to the schedule of board meetings, all other parallel project programs are advancing.

In response to the revised dates set out below, Director Technical at NMDC, Mr Narendra K Nanda stated, “NMDC is committed to moving forward on the ECT project with our partners at NLCIL. We are in the process of finalising our internal reviews and will shortly be preparing appropriate documentation for approval by the Board.”

Key dates in the lead up to the signing of the Research Collaboration Agreement include:

- NMDC board meeting for final approval 8 August

- ECT board meeting for final approval 9 August

- NLCIL board meeting for final approval 17 - 20 August (to be confirmed)

ECT’s Chief Operating Officer Jim Blackburn stated, “We have made substantial and positive progress on all parallel fronts regarding our India project.

“Our engineering, site and civil, human resource management and legal agreements/contracting programs have all made considered and demonstrable progress. Importantly this has included the drafting and review of the Research Collaboration Agreement (see below) and detailed schedules. ECT has delivered its contribution well before the target date of 31 July, and we look forward to our partners concluding the remaining formalities”.

Importantly, the revised target for completion of the remaining formalities does not materially impact the broader project delivery timeframes, as parallel project activities and programs continue to advance, including:

- Ratification of the allocation of project funding by both NLCIL and NMDC, subject to the signing of the Research Collaboration Agreement

- Establishment of the project joint bank account for the receipt and subsequent disbursement of project funds

- Continuation of site clearance and geotechnical survey activities

- Selection of the engineering firm responsible for converting the basic design package into a series of tender packages

- Conducting final interviews for the selection of ECT project engineering & management staff

Agreement Structure and Naming – Research Collaboration Agreement

Further to recent announcements (29-31 May 2018), and as the project partners progress towards completion of the detailed agreement, the partners have revised and refined the document structure and naming convention.

In the first instance, each of the detailed sub-agreements and prescribed forms (namely the Memorandum of Agreement, Master Technology License Agreement and Services Agreements) will be preserved. From a structural perspective, each of these documents will now form a schedule to a singular Research Collaboration Agreement.

Ahead of each specific schedule containing the formal sub-agreements, the Research Collaboration Agreement has a preliminary terms section which aligns with, and evolves from, the principles agreed and executed within the project agreement (MOU) signed on 30 May 2018, including:

- Part A – General terms inclusive of conditions precedent to Financial Close being

- approval to execute the document by the respective boards (inclusive of the requisite clearances and advice)

- establishment of a project joint bank account

- deposit of project funds

- Part B – R&D Collaboration

- Governance and funding of the project

- Phases and stages of the project

- Planning, budgets and performance obligations

- Part C – Special Purpose Vehicle

- Terms for the incorporation and operation of the SPV

- Accession of the SPV – transition from R&D to commercialisation phase

- Part D – Technology Licensing

- Definitions of the intellectual property (IP)

- Licensing terms and conditions

- Part E – Services Agreements

- Principle structure and terms for each of the Parties as contractors to the project

NLCIL and NMDC have requested the structure and naming of the document as set out above to facilitate a simpler and more efficient approvals process. Each of the respective boards will be asked to now approve a single document which contains these executable terms, specific detailed sub-agreements, and prescribed forms for a complete framework of project implementation.

Allocation of Project Funds

Jim Blackburn continued, “In the respective board meetings in May 2018, before the signing of the MOU, both NLCIL and NMDC not only received approval for agreement execution but also the provisional allocation of project funding. Having established the allocation, and with the confidence of having approved the detail provisions within the executed MOU, the project has gained momentum with the boards of NLCIL and NMDC. With this momentum behind the project we continue to push ahead with the establishment of the joint bank account, and process for drawdown of monies following the signing of the Research Collaboration Agreement.”

Site Clearance Preparations Continues

Further to previous announcements identifying the project site (e.g. 27 April 2018), NLCIL has continued site clearance and geotechnical activities in anticipation of project commencement.

Ashley Moore, ECT India CMD, commented, “The continuation of preparatory activity such as site clearance provides a clear indication of our partners' commitment and intent to deliver this historic project.”

An overview of the planned R&D facility is provided at the end of this announcement.

Project Engineering and Management staff recruitment

A key preparatory activity for the project in India has been the advertising, shortlisting and selection for appointment of project engineering & management staff, responsible for the day-to-day planning, procurement, construction and commissioning of the project.

ECT has led the recruitment activity and, having completed the final round of interviews this week, is well advanced in the process of building its India team as the project begins in earnest over the coming weeks.

An update on these appointments is expected to be provided by mid-August.

Engineering Firm Appointed to Deliver Project Tender Process

ECT is further pleased to announce the appointment of local Indian consulting engineering firm Geofiny to deliver the tender preparation works.

These works involve the preparation of the detailed tender documentation necessary to solicit quotes for the design, procurement and construction of the integrated Coldry and Matmor facility.

Geofiny Managing Director Mr R. Raja commented, “We at Geofiny are excited to be involved with the ECT-NLCIL-NMDC Coldry and Matmor project. It is a new technology with great potential for India and more broadly. Our works program will see a brief and intensive work schedule to support conversion of the Basic Engineering package into a series of tender packages for issue to suitable EPC and EPCM (Engineering, Procurement and Construction / Management) companies in India for the detailed design and construction program.”

This activity is scheduled to take 6-8 weeks, during which NLCIL will be proceeding in parallel with site preparations.

A more detailed overview of the project plan will be provided following financial close.

Next Steps

To recap, the immediate next steps through to financial close include:

- NMDC, ECT and NLCIL board approvals (8 - 20 August)

- Signing of agreements

- Set up of project joint bank account

- Transfer of initial tranche of project funding

As described above, progressing in parallel are several project activities and programs, including site preparation, the appointment of the project management staff and the plant and equipment tender process.

This preparatory activity supports the timely commencement of the project.

Following the signing of the Research Collaboration Agreement, the Company will provide further updates including an overview of the key terms in addition to outlining the project plan and answering further shareholder questions as they arise.

Overview of the Integrated Coldry-Matmor R&D Facility

One of the key project outcomes in July has been the completion of the Integrated Basic Engineering Design program, commissioned by ECT, and led by leading Indian engineering design firm MN Dastur.

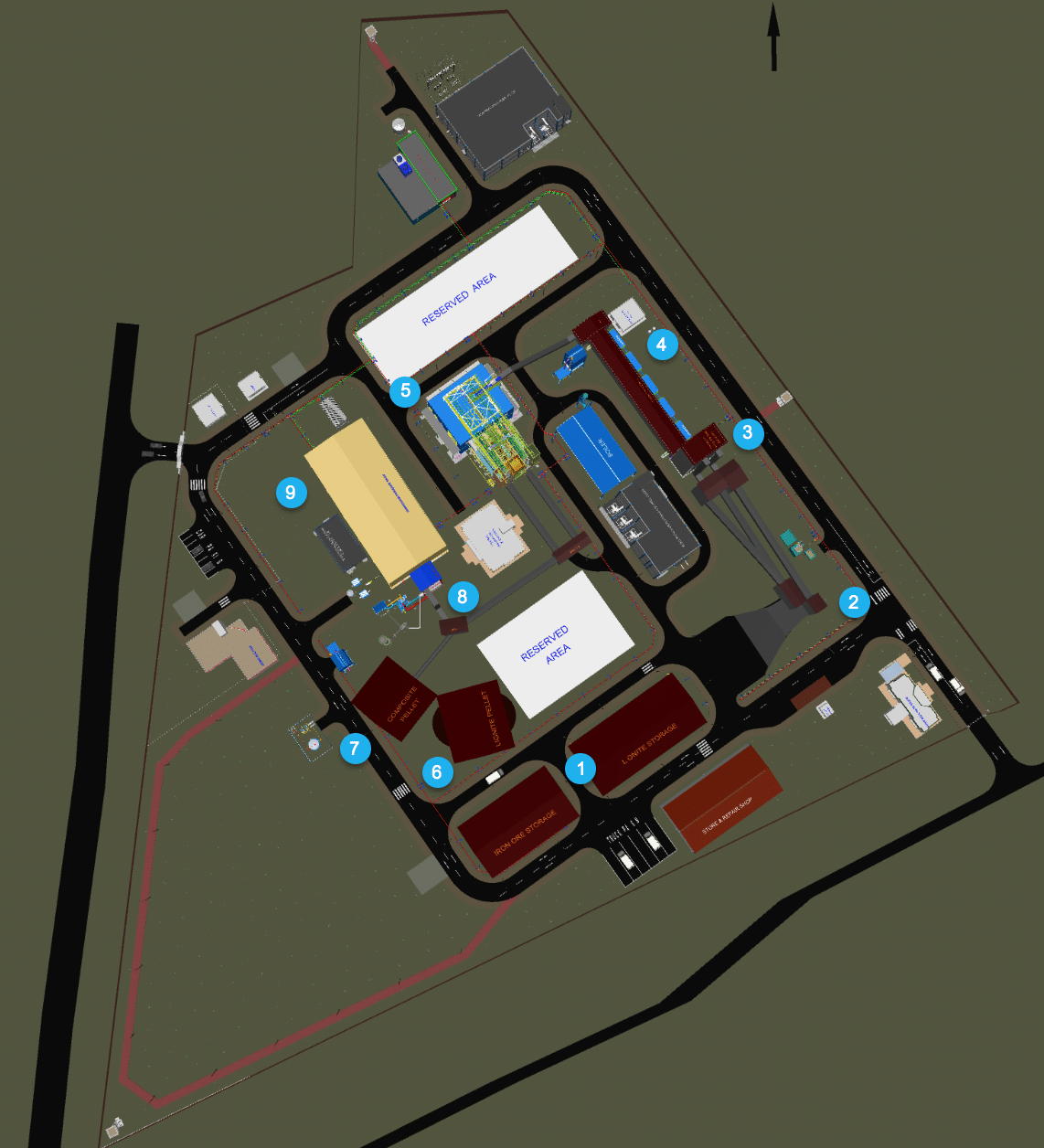

The following provides a summary of one of the key outcomes of the Basic Engineering Design program, namely an overview of the location and plant design.

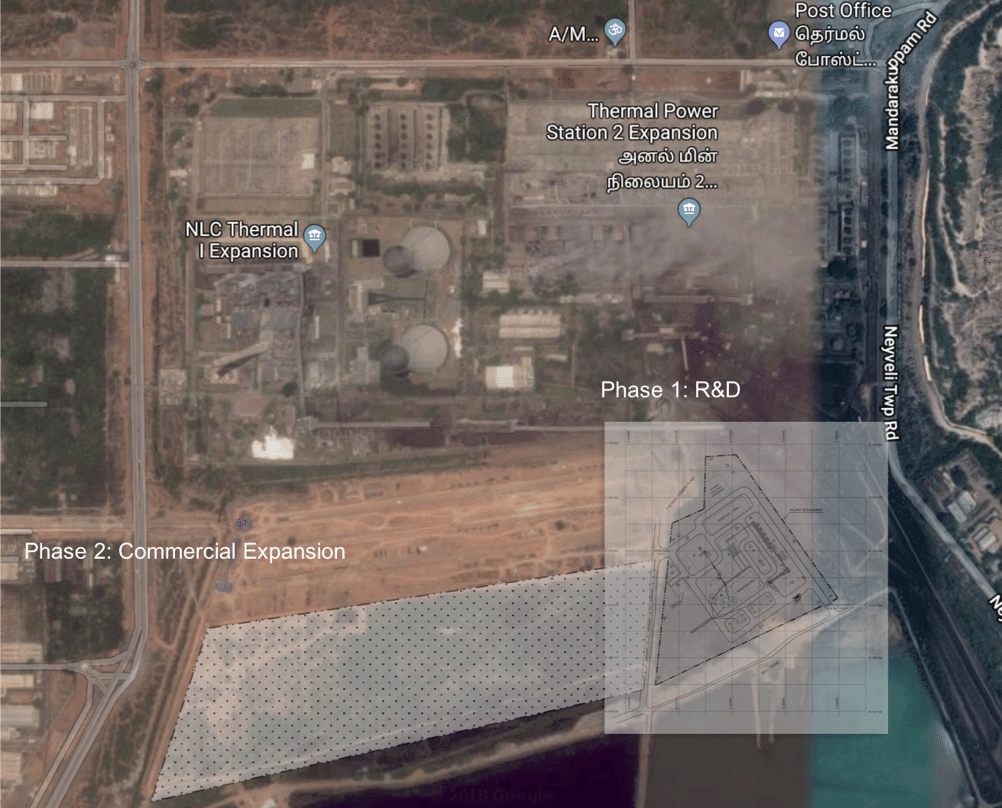

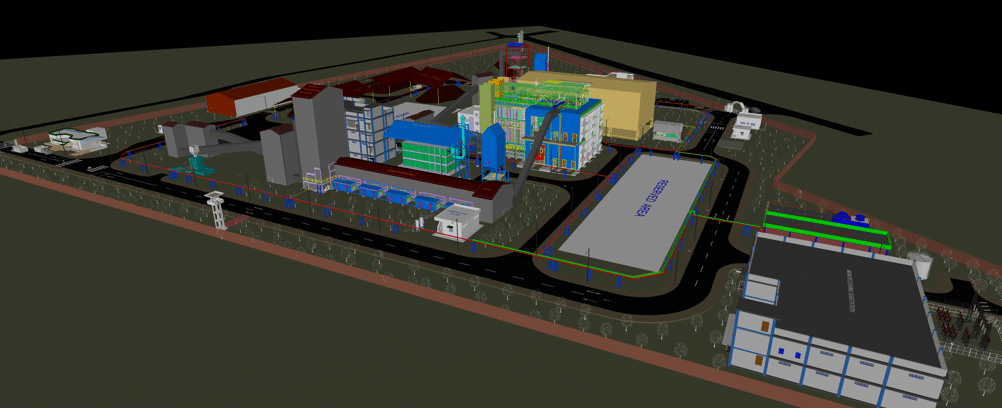

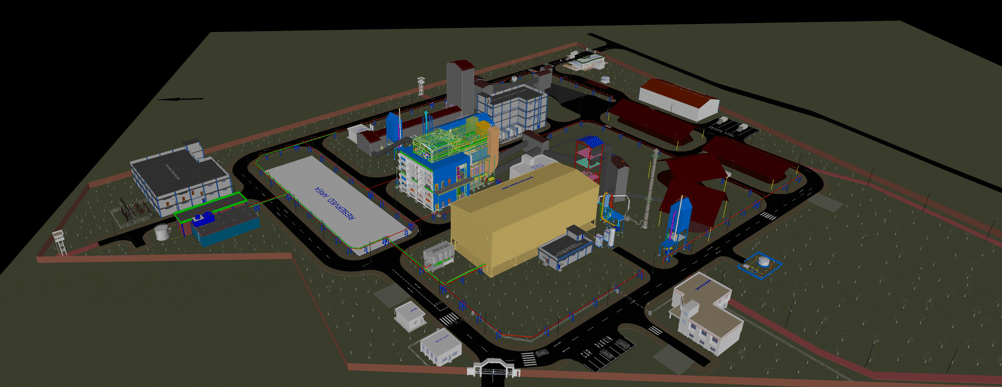

With a design capacity of 2 tonnes per hour of metal output, the plant will be located on the south side of NLCIL’s Thermal Power Station Expansion 1 and the soon to be decommissioned Thermal Station 1 (incorrectly shown in Google Maps as Thermal Station 2). The below diagram shows the placement of the R&D project and subsequent area for the expansion to the proposed 500,000 tonnes per annum (steel output) Matmor plant and beyond.

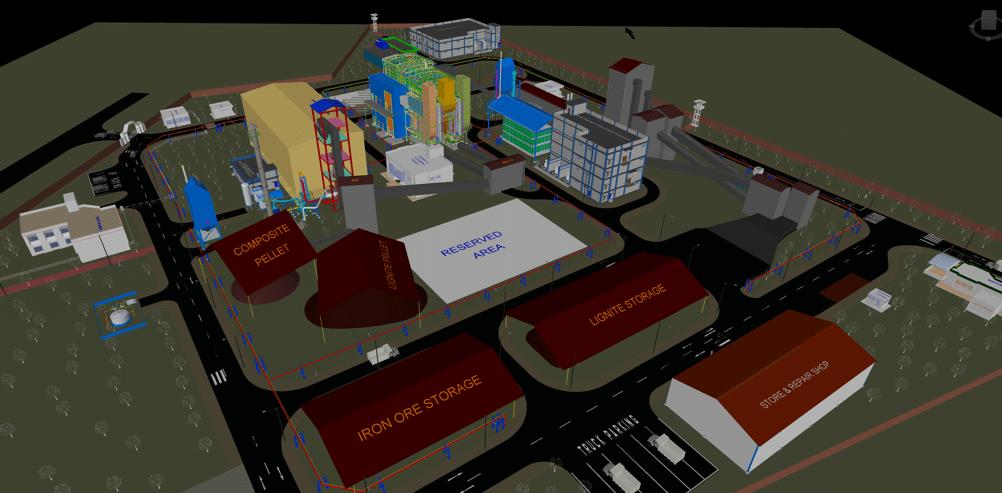

Below: aerial view of the integrated Coldry-Matmor plant.

- Raw material storage: lignite from NLCIL’s nearby mine and iron ore fines from NMDC's Kumaraswamy mine are delivered to the plant.

- Raw material in-feed handling: the plant is designed to operate in either Matmor or Coldry mode, switching between the two as required.

- Primary processing: for either Coldry solid fuel or Matmor ‘composite’ pellets takes place here involving the application of shear force to break down the lignite and initiate brown coal densification, ahead of extrusion.

- Pellet conditioning dries the surface of the pellets, reducing adhesion and increasing pellet strength before delivery to the Packed Bed Dryer.

- The Packed Bed Dryer is where most of the drying takes place. The design features the ability to hold both Matmor and Coldry pellets.

- Storage: Coldry solid fuel.

- Storage: Matmor composite pellets.

- Matmor retort (furnace) – a multiple-tube retort with 2 tonnes per hour design capacity.

- Melting & casting occurs via induction furnace following the conversion of iron oxide to iron in the Matmor retort.

Below: view of the plant from the south elevation.

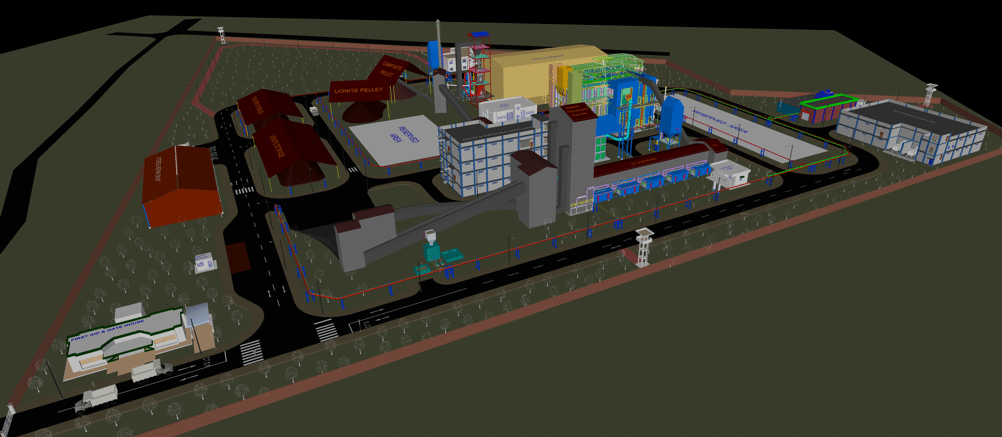

Below: view of the plant from the east. Note the gatehouse building at the bottom left-hand side.

Below: a view from the northeast shows the main substation in the right-hand foreground. The reserved area allows for future expansion of the Coldry plant.

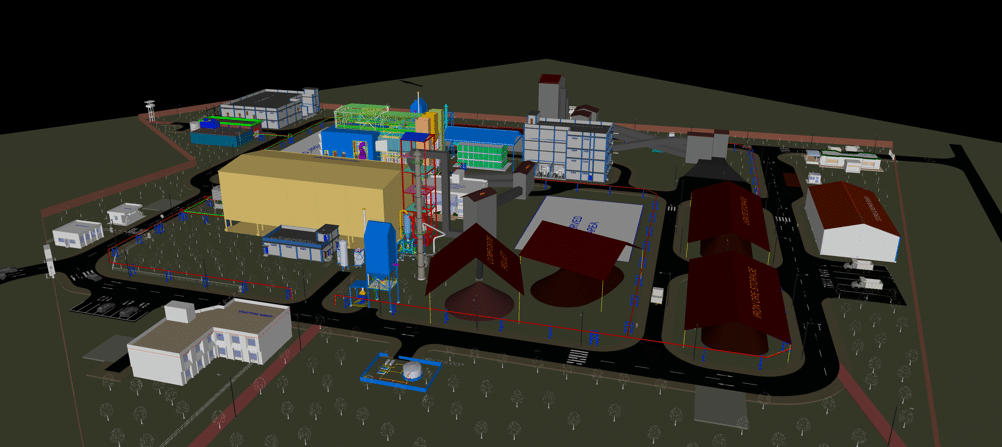

Below: view from the west, with the melting and casting building in the foreground.

Below: view from the southwest, the Matmor retort is positioned centrally between the composite pellet storage area and the melting and casting building.

For further information, contact:

Glenn Fozard – Chairman [email protected]